Looking for Prefabricated Solutions? Visit Wall-panel Prefab. Looking for Single Family Homes? visit Homes & Studios

Looking for Prefabricated Solutions? Visit Wall-panel Prefab. Looking for Single Family Homes? visit Homes & Studios

Less Expensive

Faster Turnaround

.png)

Green Building

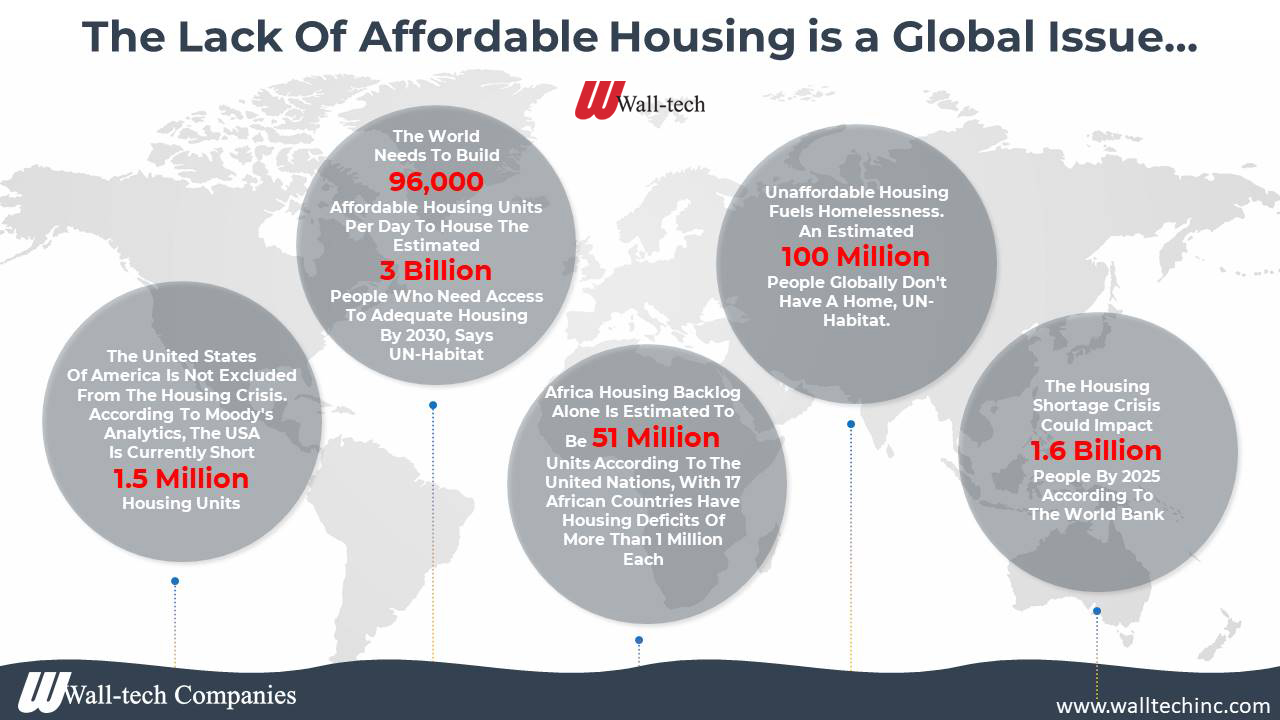

Our core belief is that dignified housing is a fundamental human right. Unfortunately, it is not available everywhere.

It is our mission to use our experience and technology to help alleviate housing crisis situations around the globe.

Our passion is teaching others how to build safe and affordable housing in their own communities.

Material costs are high and construction methods are outdated, keeping construction costs significantly high.

.png)

Traditional construction methods are notoriously slow, and the shortage of skilled labor contributes to long durations.

.png)

There isn’t an easy way to scale up to meet the huge and rapidly increasing demand.

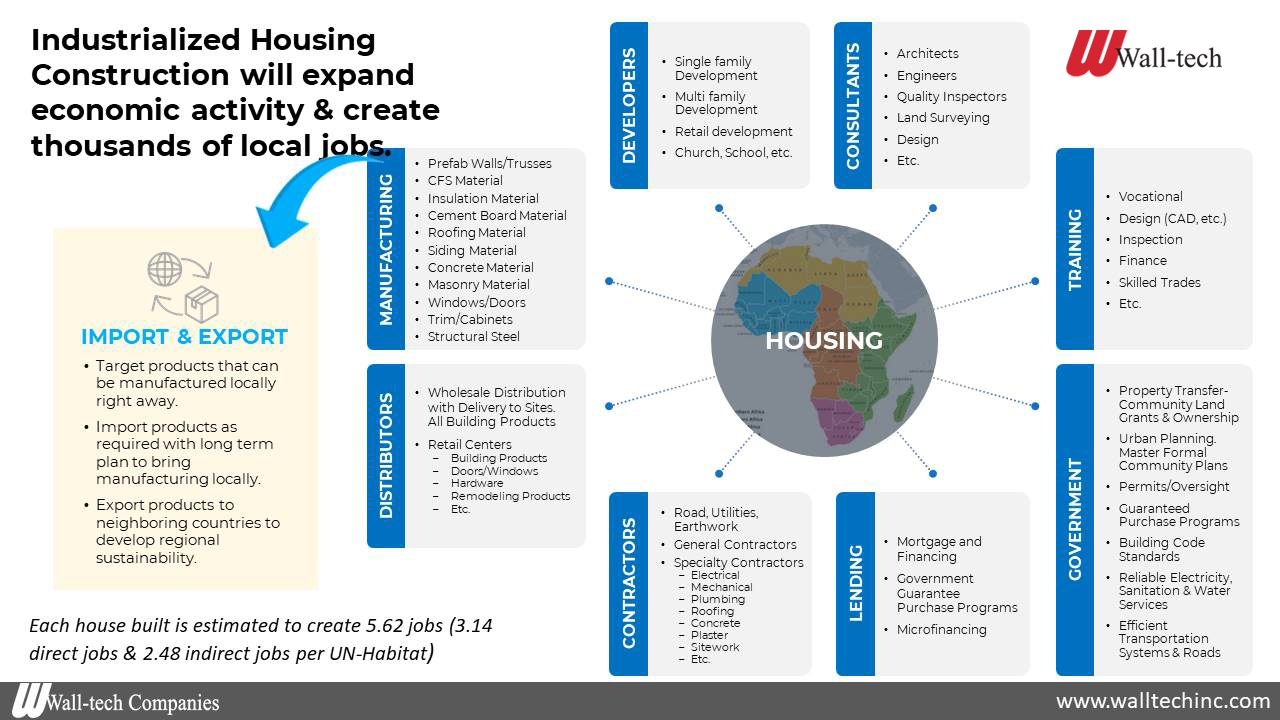

To reduce cost and more effectively control schedules without compromising quality and safety, governments, owners, and contractors worldwide are incorporating more modernized construction techniques, also known as “Industrialized Construction".

Leveraging more detailed and better-quality engineering

Effectively manage supply chains

.png)

Moving work offsite and the adoption of manufacturing-type production methods with pre-fabrication

Consistent Quality

Faster 200-300%

.png)

Better Tolerances

.png)

Safer

.png)

Less Waste(70%)

.png)

Reduced Deliveries(40%)

.png)

Metreau Apartments, Greenbay, WI - CFS enclosure resulted in $250k savings and an early delivery.

At Wall-tech, We understand what it's like to deal with unpredictable schedules and project management headaches. We are construction veterans who've been in business for 35+ years and are a recognized leader in CFS prefabrication.

We help alleviate housing crisis situations around the Globe by building resilient, high-quality and affordable housing in collaboration with the local communities.

With the use of prefabricated structural cold formed steel framing, an entire house structure can be erected in only 2-days (after the foundations are completed). For example, 100 homes can be erected per month with just 5 construction crews.

Typical construction schedule

Lower insurance rates and shorter project cycles.

Steel will not warp, split, crack, or creep when exposed to the elements.

We manufacture off-site in a controlled environment and install in half the time. Guaranteed

Our products use recycled steel and are 100% recyclable at the end of use

Steel framing resists rot, termites, and moisture

Cuts down the need for on-site waste management

Designs can be customized to fit the specifications and safety requirements of any project

Steel has the highest strength to weight ratio of any material used in construction

Complete the form below to receive the free PDF download

6135 N. American Lane Deforest, WI 53532

Have questions? Text or call us at 608-257-1595

Copyright 2025 Wall-tech and Wall-panel

All rights reserved